- Compressed air system

- HVAC System

- Spare Parts

- Rental

- Services

- Contract Air

- Design & Installation Service

- SUTO-iTEC Measuring Equipment

- News

Water source (Split)

Water source screw heat pump (Split Type Unit - E Series) 2.6kW - 21.5kW (50Hz) R410A

Mammoth Water Source Heat Pump Unit

-

Twelve Models from 3/4 to 6 tons

-

Energy efficiency up to 4.3 EER and 5.2 COP (Water Loop Condition)

-

Fully Tested with water

-

Compact size

-

CE Certificated and ARI/ISO 13256-1 rate for capacity and efficiency

-

Rotary and scroll compressors

-

MGB50 microprocessor-based control system

-

Optional Geothermal application

Unit Description

Mammoth offers a complete line of high efficiency units from 2.7 to 21 kW.

Five cabinet sizes for horizontal and four for vertical models with a similar shape allow for easy layout and installation.

Each unit is run-tested with water in the cooling and heating modes.

All units are listed for product safety by ETL.

Unit Construction

The cabinet is constructed of G-60,galvanized steel.lnternal metal parts are also fabricated from galvanized steei.Cabinet insulation is 10mm thick, skin-coated fiberglass/PE . The entire bottom panel is insulated with the same material to prevent condensation and reduce noise transmission. Three access panels for

the compressor, fan and control box sections allow service to all major components without removing the unit from the ceiling. Most competitors only offer two access

panels.The control box has its own entrance panel to limit exposure to other sections not requiring service .All major electrical components, including transformer , relays, contactor(s) and circuit board, are located inside the control box making it convenient to electrically service the unit.

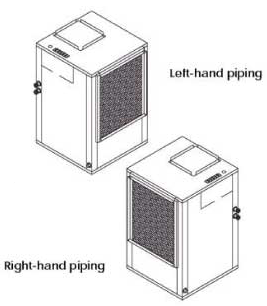

Vertical units are available in either left- or righthand piping arrangement. The handof the unit locates the water and condensate connection side as well as the main power entrance and low voltage terminal strip.The hand of the unit also locates the main access panel for access to the fan motor, control box and compressor section.

The fan section has an additional removable panel to prevent air bypass while operating the unit during service checkout.

A 10 mm thick reusable filter is supplied in a factory-mounted filter bracket designed to accommodate a return air duct connection.

The units include factory-mounted hanger brackets. and have four top-panel adjustable brackets with factory-mounted grommets.

All units incorporate female NPT water fittings outside the cabinet for connection to flexible hoses.A 22 mmO.D. condensate connection is located outside the cabinet adjacent to the water connections

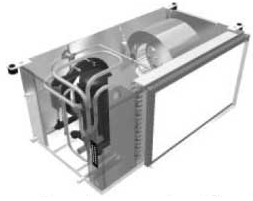

Refrigeration system

Refrigeration system for each circuit consists of a hermetic compressor ,a coaxial water-to-refrigerant

heat exchanger, an airside coil, thermal expansion valve or capillary tube,access valve,reversing valve and safety controls. The compressor is mounted on heavy-gauge mounting rails to dampen compressor vibration.ln addition, the compressor is also mounted on neoprene isolators.This dual isolation ensures minimal noise transmission and quiet operation. Each refrigeration circuit has high and low side access valves for servicing.

The water-to-refrigeration coaxial coil consists of an inner twisty tube and a steel outer tube.

Large tube diameters prevent clogging, unlike brazed type heat exchangers which require mesh strainers. The air coil is a copper-tube,aluminum finned selected for high efficiency.

The reversing valve is energized in the heating and is fail-safe to the cooling mode.

Safety controls include high and low (loss of charge protection) refrigeration pressure switches for each circuit. A lockout relay prevents the compressor from operating if any of the safeties trip.

Fan Section

The fan section consists of the fan wheel/housing assembly, fan motor and drain pan. Airside components are separated from the compressor section to limit noise transmission from the compressor.The drain pan extends past the coil into the compressor section for easy cleaning.

It is insulated from the unit casing to prevent sweating.

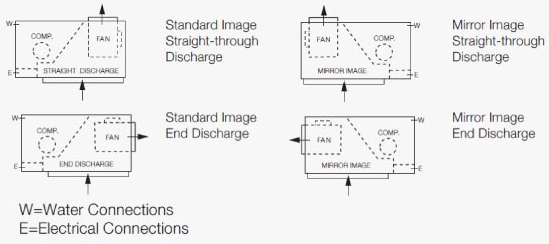

The units are capable of having two different discharge air arrangements : straight or end. Both can be factory-supplied in either configuration or simply converted from one to the other in the field. Mirror image units allow a "reversed" configuration. All units have a directdrive fan assembly.The fan motor is a multispeed, with internal overload protection.With a maximum speed of 1200 rpm, the fan is quieter than the smaller of diameter motors used in similar products. Each centrifugal fan wheel is balance for minimum vibration.

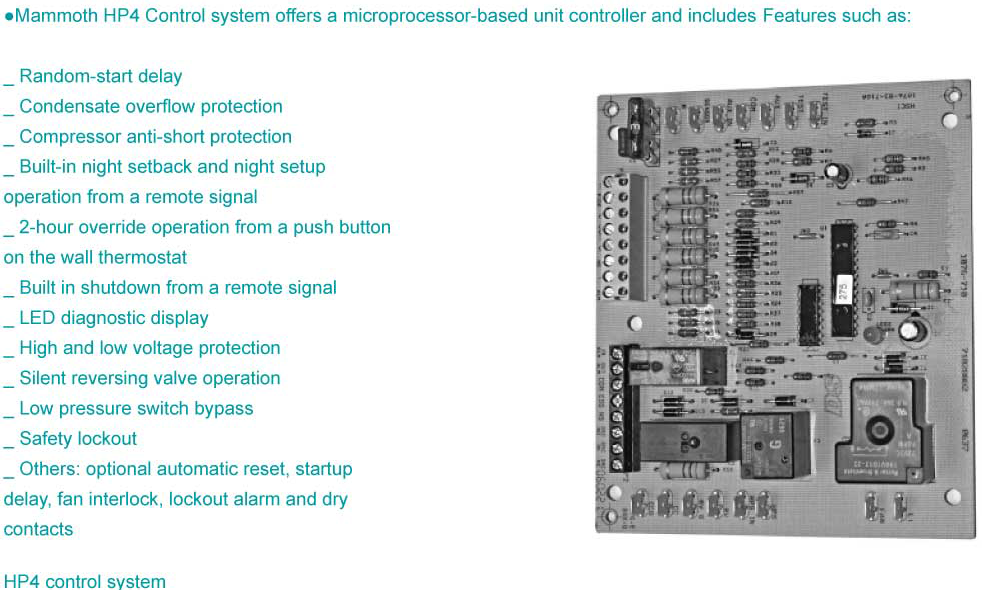

Electrical and Control Box

The control box houses all the electrical components with its own access panel.Controls include a transformer ,printed-circuit board, compressor contactor,fan relay and a capacitor(s).

-

Random start delays the startup of the unit 5 to 35 seconds after coming off from an unoccupied or shutdown cycle to prevent all the units from starting at the same time.

-

Condensate overflow protection stops compressor operation if the drain pan sensor detects moisture at the top of the pan to prevent overflow due to clogged or slowdraining condensate piping.

-

Compressor anti-short cycle protection prevents the compressor from being energized for 5 minutes after shutoff to limit compressor cycling and to extend compressor life.

-

Night setback allows heating operation at a lower set point to maintain a minimum space temperature, which is activated by a two-wire signal. The fan will cycle with the compressor.

-

Night setup allows cooling operation at a higher set point to maintain a maximum space temperature ,which is activated by a two-wire signal. The fan will cycle with the compressor.

-

Override allows night setback or setup modes to be de-activated for 2 hours while the unit resumes operation at its daytime set points. Override operation is activated by a push button on the wall thermostat.

-

Shutdown allows the units to be shut off with no compressor or fan operation in the event of an emergency. Shutdown is activated from a twowire signal.

-

LED diagnostic display communicates the status of the unit via three lights to indicate: power on. low voltage condition , high voltage condition , shutdown mode, high pressure switch fault, low pressure switch fault , freezestat fault,condensate sensor fault and compressor on.

-

High and low voltage protection shuts off the unit in the event the unit voltage is too high or too low to protect the internal components from damage.

-

Silent reversing valve operation de-energizes the reversing valve after 2 minutes each time the compressor shuts off to eliminate any swish noise.The compressor always starts at equalized pressures.

-

Low pressure switch bypass ignores the low pressure input signal for 120 seconds each time the compressor starts to eliminate nuisance trip and to allow the suction pressure to build at startup.

-

Safety lockout prevents compressor operation if any of the safety switches trip: high pressure switch, low pressure switch or optional freezestat. The unit can be reset from the wall thermostat or from the main unit disconnect.

-

Other features include: auto reset allows the unit to automatically reset itself four times within a 2 hour period, two-minute startup delay at initial startup and at loss of power, fan interlock makes sure the fan in on when the compressor is on, lockout alarm sends a signal to the thermostat to illuminate an LED and closes a set of dry contacts if any of the safety switches trip or if the unit is in shutdown mode due to a remote signal or to high/low voltage , dry contacts (set of normally open and closed) are activated when the compressor is on to operate a motorized valve.

Factory-mounted Options

Mammoth water source heat pumps offer numerous factory-installed options that can help minimize field labor and enhance system performance.

Cooling-only

Units are available for those applications requiring no heating from the unit.

An extended-range package

An extended-range package is available on all heat pump units to allow heating and cooling operation down to -5t levaing water temperature. The package includesTEV, an insulated coaxial heat exchanger and insulated refrigerant piping

25/50 mm filter

A 25 and 50 mm filter rack replaces the 10 mm rack to allow for more efficient and longer lasting

Cupronickel tubes

Cupronickel tubes on the inner tube of the heat exchanger provide additional corrosion protection in applications using well or city water.

Field-mounted Options

-

Water Flow Switch: The Water Flow Switch will shut off the unit when the water flow is smaller than limit value to protect the system.

-

Flexible hose kits: Flexible hose kits are available in, 3/4-inch and 1-inch diameters ,600mm and 900mm long. Each hose is constructed of braided stainless steel and has NPT steel fittings with a swivel at one end. Hoses are rated at minimum 1550 kPa.A clear vinyl condensate hose includes clamps for connection to the 22mm 00 condensate drain tube.

Wall-mounted thermostat:

The automatica changeover thermostat has fan ON-AUTO operation, system ON-OFF operation, digital temperature display, 2 stage electric heater display, and the thermostat can be controlled remotely. Mammoth can also provide remote controller with thermostat.

The automatica changeover thermostat has fan ON-AUTO operation, system ON-OFF operation, digital temperature display, 2 stage electric heater display, and the thermostat can be controlled remotely. Mammoth can also provide remote controller with thermostat.

Other products in category

Water-to-Water Modular

Water-to-Water Modular Water Source/Geothermal Heat Pump (Chiller) 65.9kW-315kW (50Hz)

.jpg)

.jpg)

.jpg)

.jpg)