- Compressed air system

- HVAC System

- Spare Parts

- Rental

- Services

- Contract Air

- Design & Installation Service

- SUTO-iTEC Measuring Equipment

- News

3 in 1 Water Source

Three in One Water Source Heat Pump 7.1kW - 46.2kW (50Hz) 410a

Mammoth "Three in One Water Source Heat Pump" Unit Introduction

-

Eight Models from 7.1 to 46.2kW

-

Produce hot water for space heating, Chilled water for air conditioning and domestic hot water

-

Can be applied to boiler/tower or ground-coupled (geothermal) loops

-

Can be connected to air handlers, fan coil units or gradiant floor heat system

-

Five modes of oprating cooling, heating, heat recovery, domestic hot water, heating with domestic hot water (priority is domestic hot water)

-

For floor mounted installation

Unit Feature

Mammoth Three-in-one units are designed to supply hot and/or chilled water to terminal unit such as air handling units, fan coils, and radiant floor heating systems It also can supply free domestic hot water.This applies to water loop system(boiler /cooling tower) or geothermal system .Mammoth produces Three-in-one units in 8 sizes from 7 to 46 kW with two configurations; The 024 through 072 models incorporate a single circuit refrigeration design , while 086 through 142 models incorporate dual circuit design . Each unit is fully test run in factory before shipping.

Green

Water Source Heat Pump is flexible for installation in boiler/cooling tower applications as well as ground-source (geothermal) applications with underground water or sewage water and soil as the heat source . It use R41OA refrigerant and is enviromental friendly .

Total heat recovery

During cooling mode, the unit produce 7 t: chilled water for load side and also produces free domestic hot water with heat recovery.

Construction

The cabinet is constructed of G-60 galvanization steel.Cabinet insulation is 15 mm thick , 48 kg/m3 density, skin-coated fiberglass . The entirebottom panel is insulated with the same material to prevent condensation and reduce noise transmission

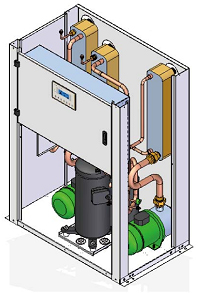

Four access panels for the compressor , pump and control box sections allow service to all major components . See Picture 1.

Refrigerant System

The refrigeration system for each circuit consists of a hermetic compressor , 3 braze-plate type water-to-refrigerant heat exchangers , thermal expansion valve , access valves , reversing valve and safety controls. The compressor is mounted on special designed mounting channel and neoprene isolators . This dual isolation ensures minimal noise transmission and quiet operation . Each refrigerant circuit has high and low side access valves for servicing.

Use stainless steel brazed-plate heat exchanger with high efficiency and anticorrosive characteristics .

Electrical and Control Box

The control box houses all the electrical components with its own access panel. Controls include a transformer ,printed-circuit board, compressor contactor, relays etc.

The control system completes with a microprocessor-based unit controller with the following features :

-

Five operation modes: Cooling, heating, heat recovery, domestic hot water, heating with domestic hot water (with domestic hot water as priority)

-

Water temperature Indication: The inlet and outlet water temperature are indicated on the thermostat.(load water , soruce water , domestic hot water)

-

Pump connection: Pump can be linked to work .(the control systom can integrate three pump connections)

-

Safety Lockout: Safety lockout prevents compressor operation if any of the safety switches trip: high pressure switch , low pressure switch , water flow switch . The unit can be reset from the wall thermostat or from the main unit disconnect.

-

Low pressure switch bypass: Low pressure switch will bypass the low pressure input signal for 120 seconds each time the compressor starts , to eliminate nuisance trip and to allow the suction pressure to build up at startup .

-

BMS communication: Use RS485 communication port to connect with BMS, see Picture 2

-

Others: Antifreezing protection; LCD error code display ; Timer-power-on/off etc .

Other Design Features Include

-

Scroll or rotary compressor(s)

-

Expansion valve(s)

-

High and low refrigerant pressure safety switches

-

Threaded water connections for source side

-

Threaded water connections for domestic hot water

-

Threaded water connections for load side

-

Insulated water and refrigerant piping

Picture 2

Other products in category

Water-to-Water Modular

Water-to-Water Modular Water Source/Geothermal Heat Pump (Chiller) 65.9kW-315kW (50Hz)

.jpg)

Water source (Split)

Water source screw heat pump (Split Type Unit - E Series) 2.6kW - 21.5kW (50Hz) R410A

.jpg)

.jpg)

.jpg)