- Compressed air system

- HVAC System

- Spare Parts

- Rental

- Services

- Contract Air

- Design & Installation Service

- SUTO-iTEC Measuring Equipment

- News

Water-cooled

Water cooled screw chiller 128kW-1,194kW (50Hz) R407c I 155kW-2,437kW (50Hz) R143a I 170kW-2,844kW (50Hz) R143a I

Mammoth MSW series water cooled chiller has wide range of application, not only work as traditional A/C but also offer water, ice storage and domestic hot water etc. for industrial use. Standard unit's cooling capacity range is from 128KW to 1914KW, divided into ten models.

Download

Superior Quality Compressor

-

Mammoth chiller uses semi-hermetic screw compressor, with no bearing leakage. Twin screw gas discharge and the new developed Y type moulding, optimized circumferential speed and advanced tooth design lead to higher compressing efficiency.

-

Motor and compressor housing are coupling forged with high precision. Double wall pressure compensated rotator shell has the extremely strength, and there is no expansion even in high pressure condition and unit noise is reduced at the same time.

-

Imported fluoride-resistant motor has high efficiency and good reliability. Twin screw heat can stand wear and tear. Using tongue shape round seal to isolate the the bearing cavity to get a lower axial cavity pressure. Motor thermal protection PTC will keep its safety operation.

-

The oil line design, inner patented three grades oil separator, and the long life expectancy with µm grade precise filter. Hermetic low pressure bearing cavity improves lubrication, the de-pressurized bearing room, ensures minimum refrigerant mixed in oil, the oil's viscidity will be higher. Compared with normal design, the oil's viscidity will be improved nearly up to 1 time. Oil is supplied by pressure difference, and it is not necassary to design additional complicated oil system, like oil cooler and oil pump etc. Compressor is direct driven by motor with less moving components reduces wear and tear, and gains high mechanical efficiency. Optional stepless slide valve control with VI compensation.

High Efficiency & Energy Saving

-

Nowadays, the production of water cooled chiller put more attention on lower initial investment rather than lower operation cost, which lead to the descending of heat exchanger performance and declining of COP.

-

However, Mammoth has its own solution for those wasted energy. Mammoth has focused on energy saving at the very start, keep good performance on every detail. Mammoth MSW chillers are rated in accordance with USA ARI.

-

The condenser and evaporator of this series are shell and tube type with new high efficiency structure. The heat exchanger adopts the most advanced high efficient copper beams, its special geometrical characteristics enhance vaporizing core for core boiling of outside pipe, strengthen fluid turbulence and postpone water side dust deposit; reinforced heat transfer of inner and outer wall makes the transfer efficiency increased 30% compared with previous design. Inner groove of evaporator and condenser tube upgrades the transferring efficiency, as well as the evaporating temperature and then improves the unit COP.

-

The minimum refrigerant flow rate passed on evaporator is 6m/s, which ensures oil self-flow with the refrigerant back to compressor without any compulsive oil return facility, it prevents compressor damage caused by lack oil.

-

The design, production and inspection of every vessel reach the standard/rules of GB150 <Steel Pressure Vessel> GB15 <Tubular heat exchanger>, JB/T4750-2003 <Pressure vessels for refrigerant equipment> và Supervision Regulation On Technology For Stationary Pressure Vessel and reliable work.

Part Load Performance

-

Compressor is mostly working under part-load condition, unit should work in high efficiency not only in fully but also in part-load condition. It is normal that operation cost has 10% - 20% variation due to the partial load under same condition, The operation energy consumption in part-load condition is vital to unit running cost, and in AR1550 it is measured by Integrated Part Load Value (IPLV) and Application Part Load Value (APLV). IPLV and APLV porovided a standard measurement of part-load operation, so partial load should be defined as normal application rather than special situation.

-

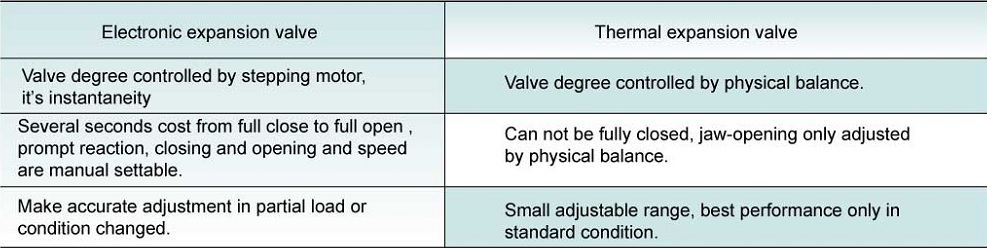

Mammoth screw chiller has been fully considered the economic operation in part-load condition. Utilization of electronic expansion valve improves unit efficiency. Electronic expansion valve has the technology of PID, which cut down the working cost. The valves integrated with expansion valve motor, ceramic valve plate and valve port wears resistance, has high reliability and long life expectancy. A linear change of water flow, continuously cooling capacity adjustment, make no fluid strike to compressor in cooling circuit. In part-load condition, Electronic expansion valve can create higher accuracy of adjustment, then improves part-load efficiency, and the operation efficiency upgrades 15% compared with thermal expansion valve units, and more accurately controls on chilled water temperature.

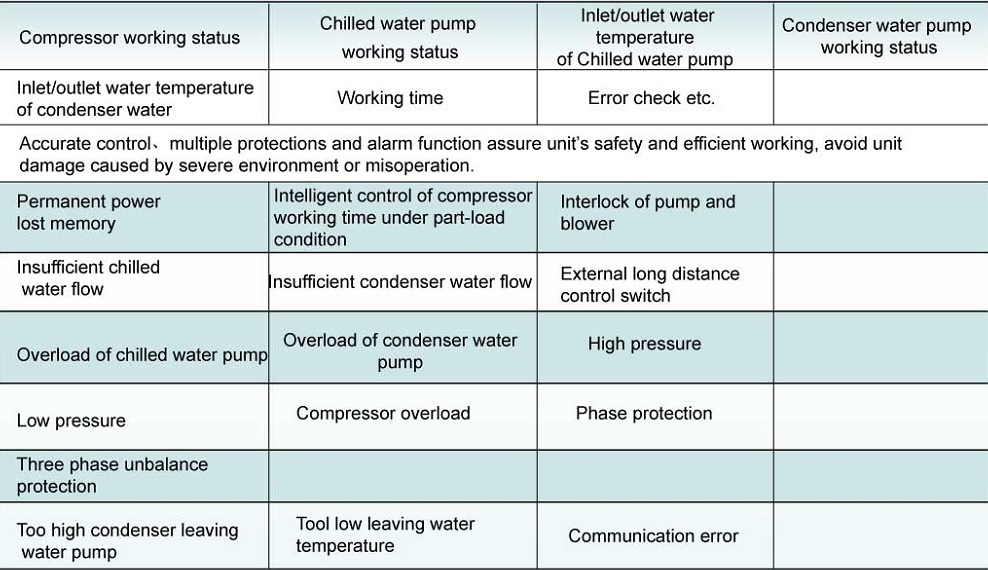

Automatic Control

-

Electrical control system uses first class electrical components, and there are many automatic protection functions; unit is monitored and managed by microprocessor, and can be linked with water pump & cooling tower, and also can be central controlled through communication port, with the compatibilities of Building Automation System(BAS)

-

English display, optional can display many working datas, which can fully indicate unit operation status. Optional touch screen displayer.

Easy Installation: Each unit has been fully tested before leaving factory, filled with oil and refrigerant. All protection switches have fully set in factory, and just connect power supply and water pipes at site only.

Wide spread Application:

-

Mammoth MSW series are suitable for office building, hotel, restaurant and hospital etc., and offering higher than 5 C chilled water If in low temperature mode (optional), the unit can be used for freezing processing, chemical industry and ice storage. Add antifreeze into water system to get -10 C - 5 C chilled water.

-

In heat recovery mode(optional), it is free to supply domestic water in cooling mode; the domestic hot water temperature ranges from 45 C - 65 C according to different refrigerant. The design of heat exchangers separated condenser water and domestic water, which ensures no water mixture pollution.

-

If the use marine water as condenser water is the sea water, Cupronickel heat exchanger is a good solution on anticorrosion.

Other products in category

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)