- Compressed air system

- HVAC System

- Spare Parts

- Rental

- Services

- Contract Air

- Design & Installation Service

- SUTO-iTEC Measuring Equipment

- News

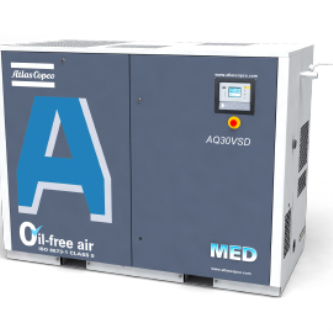

Oil-free tooth compressors

ZT-MED: Oil-free tooth compressors for medical applications

Atlas Copco’s ZT-MED oil-free rotary tooth compressors meet your needs for pure, oil-free air while offering wide pressure ranges and improved energy efficiency. Developed especially to be a part of a Medical Air Plant, they provide the highest levels of reliability and air purity. ZT-MED compressors eliminate the risks of oil contamination, as well as the resulting extra costs. These ISO 8573-1 CLASS 0 certified compressors are easy to operate and maintain.

Customer benefits

-

Certified 100% oil-free air – ZT-MED compressors provide 100% pure, clean airthat complies with ISO 8573-1 CLASS 0 (2010) certification. CLASS 0 means zero risk of contaminating hospital pipelines; zero risk for patients; zero risk of damaging expensive equipment (e.g., anesthesia machines); and zero risk of damaging your hospital’s hard-won professional reputation. In 2006, Atlas Copco was the first manufacturer in the world to receive such certification for an oil-free compressor.

-

Quiet operation – The vertical layout of the coolers reduces the noise levels from the fan, motor and element. Moreover, ZT-MED compressors are supplied in a sound-insulated canopy, thus avoiding the need for additional sound isolation.

-

Advanced control and monitoring – To maximize efficiency and reliability, the Elektronikon® MkV controls the main drive motor and regulates the system. In combination with the ES-Medical Central Controller, your Medical Air Plant is under full control and monitoring.

Easy maintenance – The robust air inlet filter offers a long lifetime and high reliability for long service intervals and low maintenance needs. -

Full compliance – The Medical Air Plant uAIR series based on ZT-MED compressors is precertified according to MDD 93/42/EEC, which simplifies your installation and commissioning process. It is designed and manufactured according to ISO 9001, ISO 14001 and the ISO 13485:2003 quality management system and surpasses the requirements of the most demanding standards and regulations such as:

-

Medical Device Directive MDD 93/42/EEC

-

European pharmacopoeia

-

EN ISO 7396-1

-

ISO 14971

-

Health Technical Memorandums HTM 02-01 and HTM 2022.

-

Technical data

| Capacity FAD (l/s, cfm) | 21 - 48 l/s |

|---|---|

| Max working pressure | 10 bar |

| Installed motor power | 15 - 22 kW |

| Weight | 1060 - 1086 kg |

.jpg)

.jpg)